What is the difference between the extrusion process of Rigi

栏目:Industry News 发布时间:2021-06-03 15:19

There are indeed many Rigid vinyl compound extrusion methods, such as vacuum forming, cold top (hard top) forming, co-extrusion and so on. If high productivity is required, and there are no special requirements on the surface of the product,...

There are indeed many Rigid vinyl compound extrusion methods, such as vacuum forming, cold top (hard top) forming, co-extrusion and so on.

If high productivity is required, and there are no special requirements on the surface of the product, most of them choose vacuum forming (mold) to vacuum. If the product surface mirror effect or high filling profile and pipe extrusion are required, cold top (hard top) molding is generally selected, but the production efficiency of hard top molding is relatively low and the extrusion speed is relatively slow. The advantage is that the surface of the product is smooth and clean. High filling materials can be used.

Hard top molding is to directly use the shape of the mold, and the material is directly ejected from the screw die through the mold. Generally, the product is cooled by water after the mold is ejected. Vacuum forming generally has a certain stretch forming ratio from the die, so the material is required to be relatively tough and strong, and the addition of fillers is relatively small.

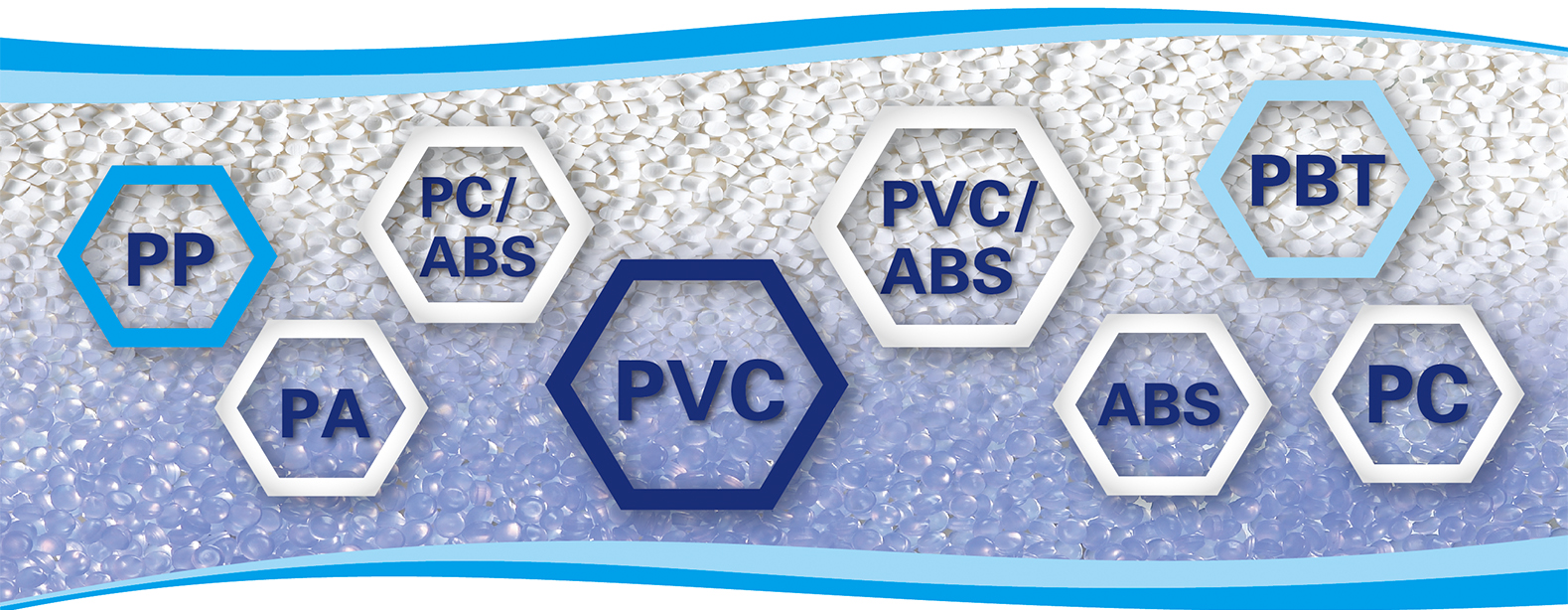

Wuxi Jiahong Plastic Technology Co., Ltd. can dye and process ABS, PS, PC, PC/ABS, PP and other engineering plastic particles according to customer requirements; various filling, flame retardant, reinforced modified ABS, PP, PC/ABS, PA and other engineering plastics Particles; various automotive special materials such as door panels, bumpers, dashboards, engine covers, car lights, etc.

Wuxi Jiahong Plastic Technology Co., Ltd. has nearly 30 years of experience in R&D and pelletizing production of Rigid vinyl compound, and experience in R&D and production of modified engineering plastics; the professional technical service team can provide customers with one-stop modified plastic system solutions. If you want to know more about the product, please log in to our official website: www. js-plastics. com, consult online customer service or call the hotline. Landline: 0510-68755207 Mobile: 15190220696, we will serve you wholeheartedly.

If high productivity is required, and there are no special requirements on the surface of the product, most of them choose vacuum forming (mold) to vacuum. If the product surface mirror effect or high filling profile and pipe extrusion are required, cold top (hard top) molding is generally selected, but the production efficiency of hard top molding is relatively low and the extrusion speed is relatively slow. The advantage is that the surface of the product is smooth and clean. High filling materials can be used.

Hard top molding is to directly use the shape of the mold, and the material is directly ejected from the screw die through the mold. Generally, the product is cooled by water after the mold is ejected. Vacuum forming generally has a certain stretch forming ratio from the die, so the material is required to be relatively tough and strong, and the addition of fillers is relatively small.

Wuxi Jiahong Plastic Technology Co., Ltd. can dye and process ABS, PS, PC, PC/ABS, PP and other engineering plastic particles according to customer requirements; various filling, flame retardant, reinforced modified ABS, PP, PC/ABS, PA and other engineering plastics Particles; various automotive special materials such as door panels, bumpers, dashboards, engine covers, car lights, etc.

Wuxi Jiahong Plastic Technology Co., Ltd. has nearly 30 years of experience in R&D and pelletizing production of Rigid vinyl compound, and experience in R&D and production of modified engineering plastics; the professional technical service team can provide customers with one-stop modified plastic system solutions. If you want to know more about the product, please log in to our official website: www. js-plastics. com, consult online customer service or call the hotline. Landline: 0510-68755207 Mobile: 15190220696, we will serve you wholeheartedly.