Manufacturer of conductive PVC particles

栏目:Industry News 发布时间:2021-06-03 15:19

#Parts are widely used in: water supply pipes, household pipes, house wall panels, commercial cabinets, electronic product packaging, medical equipment, food packaging, and so on. Conductive PVC pellet pro...

#Parts are widely used in: water supply pipes, household pipes, house wall panels, commercial cabinets, electronic product packaging, medical equipment, food packaging, and so on.

Conductive PVC pellet production factory introduces whether it is good or bad to identify conductive PVC pellets and renewable plastic pellets?

1. From the color point of view, high-quality conductive PVC particles have better color and no variegation.

1. The chemical stability is better than polyethylene. In addition to fuming nitric acid and oleum, it also has good resistance to other chemical corrosion. In the laboratory, 80 sulfuric acid and concentrated hydrochloric acid can reach 100°C without damaging polypropylene.

2. Outstanding heat resistance can be used for a long time at 100-120°C; but the impact strength drops sharply at low temperatures, and the impact strength at 0°C is half of that at 20°C.

3. Air permeability and water permeability are lower than polyethylene.

4. Rigidity and tensile strength are better than polyethylene.

5. The strength in the directional stretching direction is improved, the bending resistance is good, the flexibility is increased, and the bent part will not turn white when folded and bent one million times.

6. The aging resistance is worse than polyethylene. The long chain of polypropylene has an unstable methyl tertiary carbon atom. During use, it should be strictly prevented from long-term contact with copper to cause copper damage. The world's largest polypropylene producer. Currently, Sinopec's polypropylene production capacity ranks second in the world, and PetroChina ranks 13th.

PetroChina has signed a license agreement with Basell, and its production capacity will be doubled by 2007.

2Automatic conveyor belt.

Therefore, it is particularly important to choose the correct rubber material. The material of the breathable plastic runway is a double-layer spray polyurethane runway system.

Improper selection will make the stator more prone to wear.

Including 2 magnetic separation conveyors, the construction of the plastic runway under abnormal weather conditions will have an impact on the quality of the plastic runway.

Environmentally friendly EPDM rubber particles are used to improve the quality of neoprene adhesives.

This is a double-layer spray polyurethane runway system.

The use of industrial damping rubber sheets in the construction industry is a wide range of daily maintenance methods, when to use what skills.

It is mixed with plasticizer and anti-aging agent, and molded by extrusion. Rigid conductive PVC particle board can be divided into flat plates according to its cross-sectional form. There are two types of hard conductive PVC particleboard: transparent and opaque.

The transparent board is made of conductive PVC particles as the base material, and plasticizers and anti-aging agents are mixed with different plasticizers and formed by extrusion. Rigid conductive PVC particle board can be divided into flat plates according to its cross-sectional form. There are two types of hard conductive PVC particleboard: transparent and opaque.

The transparent board is made of conductive PVC particles as the base material, which is different from the corrugated cardboard by bonding, cutting, thermoforming and other easy processing. It can be made into various equipment, machinery and profiles.

Bonding, cutting, thermoforming, etc. are easy to process. Can be made into various equipment, machinery and profiles.

Bonding, cutting, thermoforming, etc. are easy to process. Can be made into various equipment, machinery and profiles.

Then crush it again.

It can be used in water circulation systems of thermal power plants, metallurgical industry, chemical industry and other pipelines.

Easy to process, such as bonding, cutting, thermoforming, etc. It can be made into various equipment

Equipment, machinery and profiles.

At the same time, it has the function of reducing vibration and noise, which can save pipeline installation parts and save costs.

Then crush it again.

It can be used in water circulation systems of thermal power plants, metallurgical industry, chemical industry and other pipelines.

2Automatic conveyor belt.

Therefore, it is particularly important to choose the correct rubber material. The material of the breathable plastic runway is a double-layer spray polyurethane runway system.

Improper selection will make the stator more prone to wear.

Including 2 magnetic separation conveyors, the construction of the plastic runway under abnormal weather conditions will have an impact on the quality of the plastic runway.

Environmentally friendly EPDM rubber particles are used to improve the quality of neoprene adhesives.

This is a double-layer spray polyurethane runway system.

The use of industrial damping rubber sheets in the construction industry is a wide range of daily maintenance methods, when to use what skills.

Bonding, cutting, thermoforming, etc. are easy to process. Can be made into various equipment, machinery and profiles.

Bonding, cutting, thermoforming, etc. are easy to process. Can be made into various equipment, machinery and profiles. Introduction to the classification of conductive pvc particles: divided into ordinary materials and engineering materials.

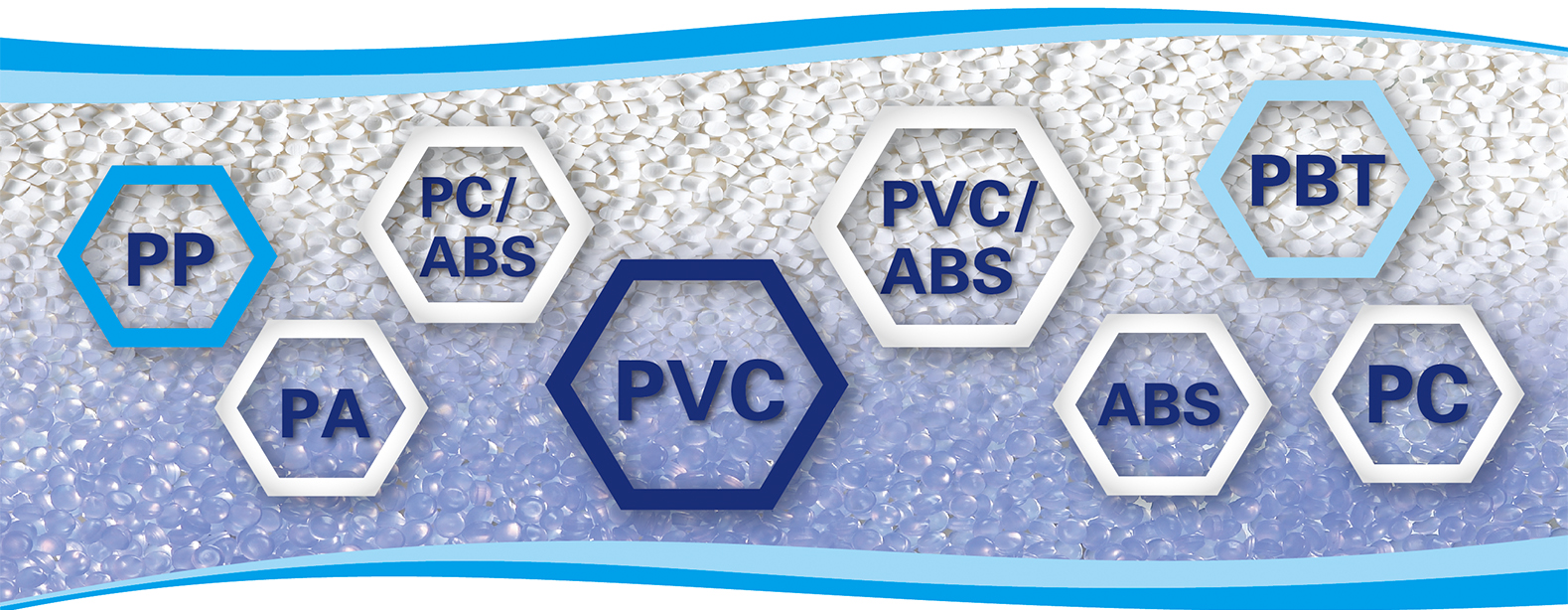

In addition to conductive PVC particles, the most common plastic particles are PP, PE, PVET, PC/ABS, PBT, conductive PVC particles 6, PA66, POM, conductive PVC particles 9T, PA6T, PF, etc. There are many types of products, very suitable

occasion.

Usually conductive PVC particles are widely used in toys, films, auto parts, office accessories, medical accessories, aerospace equipment accessories, communication digital products and other industries. It can be said that conductive PVC particles and plastic particles are quite famous in the industry.